Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Модель: B60Ex

марка: Calstar

Подробности Упаковки: Wooden box

производительность: 500set

транспорт: Ocean

Место происхождения: Shenzhen, China

Поддержка о: 10 sets per day

Сертификаты : ISO14000,ISO9001,Ex,CE

Код ТН ВЭД: 8419.4090.90

Порт: Shenzhen

Вид оплаты: L/C,T/T

Инкотермс: FOB

Solvent Recovery Machine in Suva

Petroleum ether can clean metal mechanical parts .Calstar Solvent Saver provide Metal Fabrication & Finishing industries with the recycling equipment needed to not only reduce waste, but save money!

We specialize in recycling equipment for liquid waste generated in the metal finishing industry.

Did you know that on-site recycling could reduce your solvent purchases by as much as 95%, as well as dramatically reduce your hazardous waste? Solvent Recovery Machine in Suva

After waiting 2-3 hours, waste solvent has been reclaimed and you will get clean solvent to use!

Customer Benefits

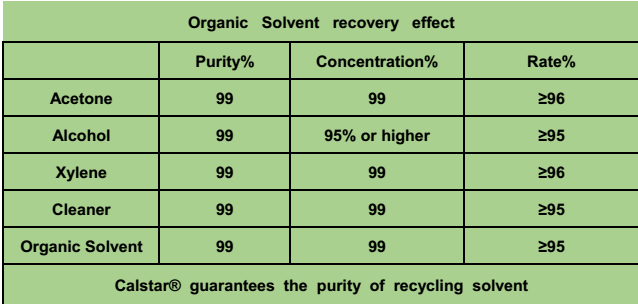

●High quality solvent recovery: clear, pure, good performance;

●Low maintenance cost, easy to maintain;

●Easy operation and installation: recovery process and operation is simple, convenient. General staff can secure posts after short-term training;

●The equipment is compact, small and light, space saving;

●Short process time and short operation time;

●Less investment, pay back quickly on investment; well-preserved environment and high economic benefits with less investment.

Characteristic

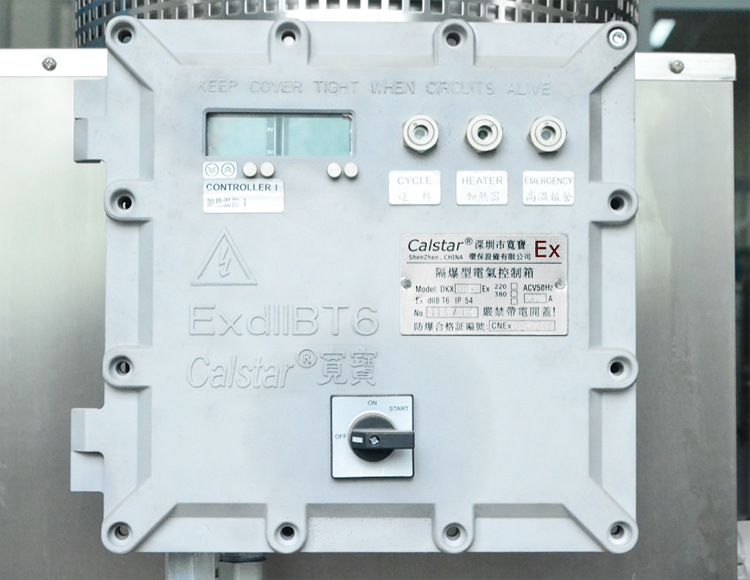

●Explosion-proof electric equipment: in compliance with Chinese safety standards (CNEX) and European standards (ATEX), worry-free and safe for use;

●Self-developed standardized production, stable and durable quality assured, has good performance;

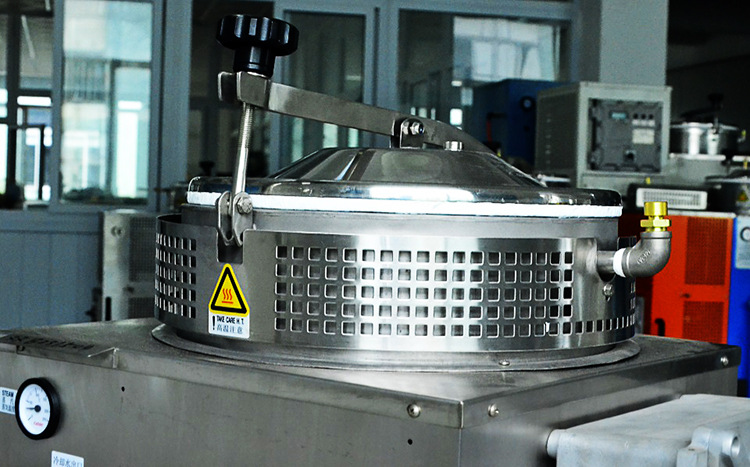

●Stationary structure, safe structure; slag discharge valve in the recovery tank bottom, only pull the slag discharge valve handle to clean residues;

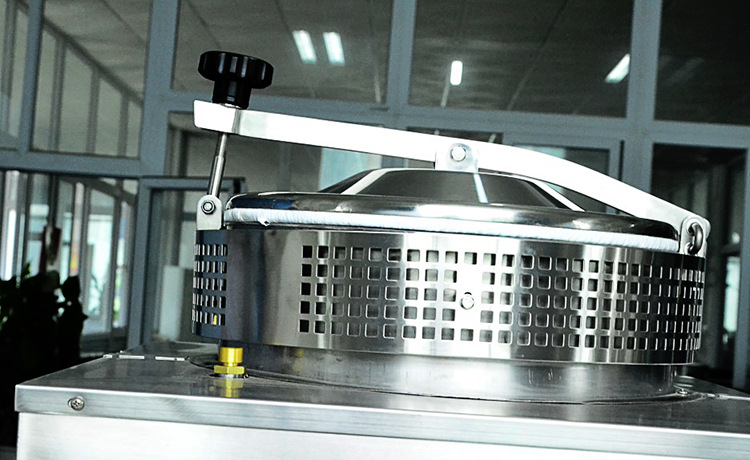

●High quality durable stainless steel tank, prevent chemical corrosion; two-tier structure, indirect heating, reinforcement barrelhead design, precise temperature control, explosion-proof, anti-leakage;

●Heating Method: heat medium (heat transfer oils) indirect heating;

●water-cooled condensing system: cooling is faster, recovery is rapid; cooling faster than air-cooled models, more rapid recovery with a shorter time;

●Fully stainless steel enclosure: greasy dirt can be gently wiped clean, dirty easy to clean, so that equipment is always kept clean and new;

●Digital heating temperature controller: advanced numerical performance, safety intuitive, accurate and convenient heating temperature control;

●Multiple operational safety protection functions: pre-set temperature shutdown function; timer shut off function; ultra-high temperature protection features; high-voltage protection function; power failure protection function.Solvent Recovery Machine in Suva

Customizing & Auxiliary device:

※You are free to customize the equipment to meet your specific needs, or choose auxiliary device in compliance with your needs in order to achieve the desired treatment effect.

Technical Parameters:

(for reference, the data subject to change, please with your choice models the actual date).

|

Model |

Feeding |

Heating |

Socket |

Time |

Dimension |

Weight |

|

B60Ex |

60L |

50~190°C |

220ACV/50Hz |

3Hr |

587*827*1480mm |

104Kg |

NOTE: Values listed above, the recovery time is under ideal conditions in laboratory test values during recovery of toluene for reference. The actual operation in the process of recovery and the waste solution inside the impurity content, high and low boiling point solvents, environmental temperature, viscosity, etc. differ.

Application Fields:

Calstar solvent recycling machines are applicable to reclaim most of common organic solvents. As long as you have a solvent recovery and treatment needs, recyclable processing industries in common organic solvents, no matter what kind of industry.

The equipments have been widely used in various industries at home and abroad.

1.Automobile manufacturing and repair industry:

vehicle spraying equipment and spray gun cleaning pipeline thin materials, such as: naphtha, toluene, xylene, methyl ethyl ketone, n-butyl, etc.; clean gasoline engine produced by such processes as solvents.

2.Electronic product manufacturing industry (e.g.: LCD, LED, etc.):

cleaning mold, cleaning of electronic products themselves cleaning agents, such as: ethanol, acetone, trichloroethylene, etc.

3.Precision instruments and hardware manufacturing industry:

cleaning mold and processed products, organic solvents, such as: naphtha, hydrocarbons, kerosene, gasoline and other solvents.

Группа Продуктов : Машина для восстановления растворителей > Машина для восстановления растворителей с водяным охлаждением

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.